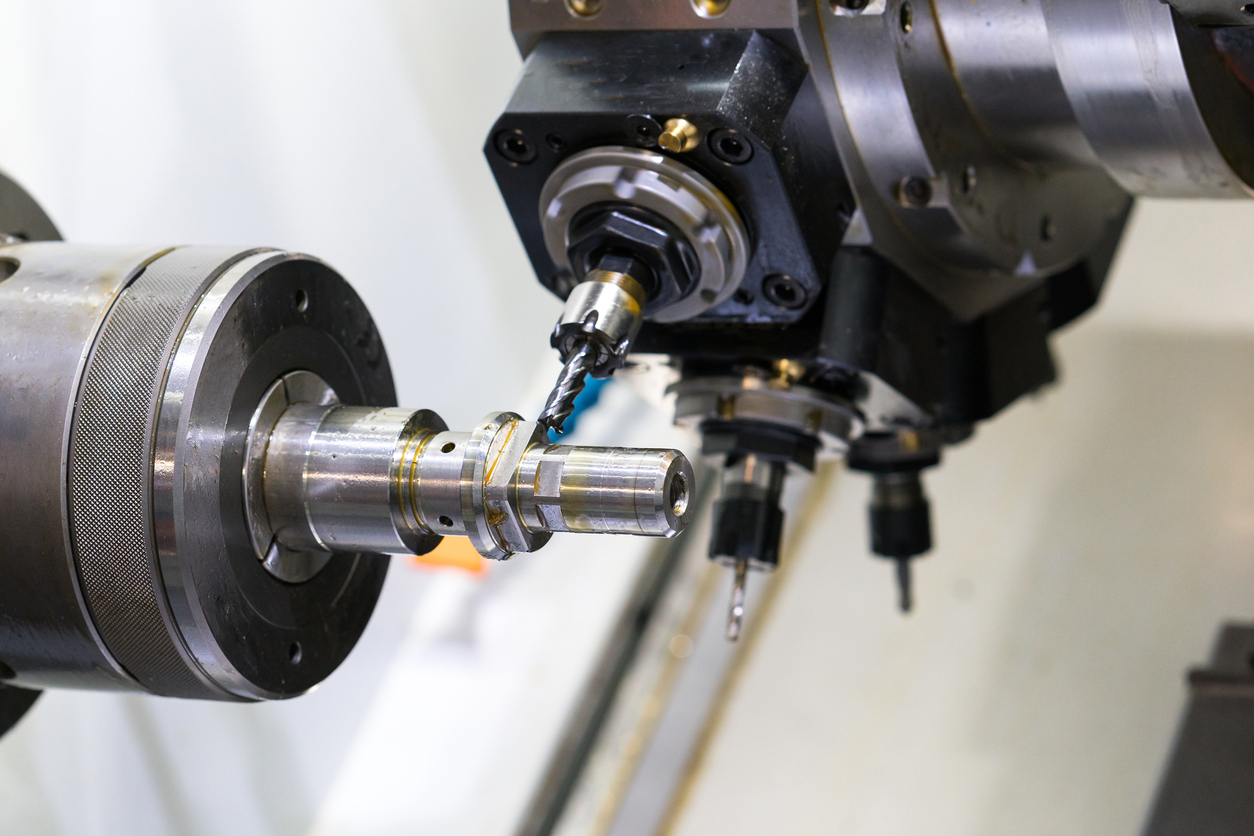

One of the most effective services in precision machining manufacturing is CNC turning. In this process, a lathe is controlled by a computer program and removes material from a rotating component until the desired shape is reached. This process is vital in creating quality precision machined components. CNC turned parts are utilized often in the manufacturing sector, such as gears, shafts, or pins. Let’s dive into the advantages of using CNC turned parts in precision manufacturing — and then investigate why Alco is the perfect manufacturing partner for you.

Essential Benefits of Precision CNC Turned Parts

CNC turning can offer you many benefits, including enhanced accuracy and precision. CNC turning relies on CAD software, which is a program that uses 3D models to visualize the design and then essentially instruct the CNC turning machine to manufacture the workpiece according to the design. These detailed models allow for greater precision during the manufacturing process, and complex parts can be produced according to incredibly specific dimensions, boosting the overall quality of the finished products.

Because of this enhanced precision, you can expect cost-savings as well. These parts are typically accurate, and because of this, there is a lessened need for reworks or replacements. This leads to reduced material waste, which helps you conserve your budget. With these shortened lead times, CNC turning produces faster results, allowing you to reach the market more quickly.

In addition, CNC turning delivers consistent and reliable components, making it an ideal choice for high-volume production. Scalability is important, and it’s essential to find a manufacturing process that supports this. Finally, CNC turning is compatible with a wide range of different materials, including steel, stainless steel, brass, and aluminum. This allows for greater variety and flexibility in design so you can ensure your components match your specific needs.

Alco Offers Exceptional CNC Turned Components to Match Any Application

At Alco, we understand the benefits CNC turning brings, which is why we’re proud to provide our customers with high-quality CNC milling and turning services. With our cutting-edge equipment, you can expect world-class parts for whatever application you may need.

We provide other exceptional precision machining services as well, including Swiss machining, multi-spindle screw machining, tooling design and prototyping, and more, such as important secondary services that extend the longevity and enhance the aesthetics of your products.

We hold a number of valued ISO certifications, and we’re also ITAR-registered, making us an ideal partner for defense manufacturing. In addition, our company spans over seven facilities, with locations from Michigan to New York. These locations allow us to perform specialized services, which helps us achieve lean manufacturing and competitive prices. For over 50 years, we’ve been committed to supporting our customers with whatever they may need, and we’re dedicated to matching exact specifications.

Are you ready to level up your next project? Get in touch with Alco today for world-class CNC turned parts that will exceed your expectations.