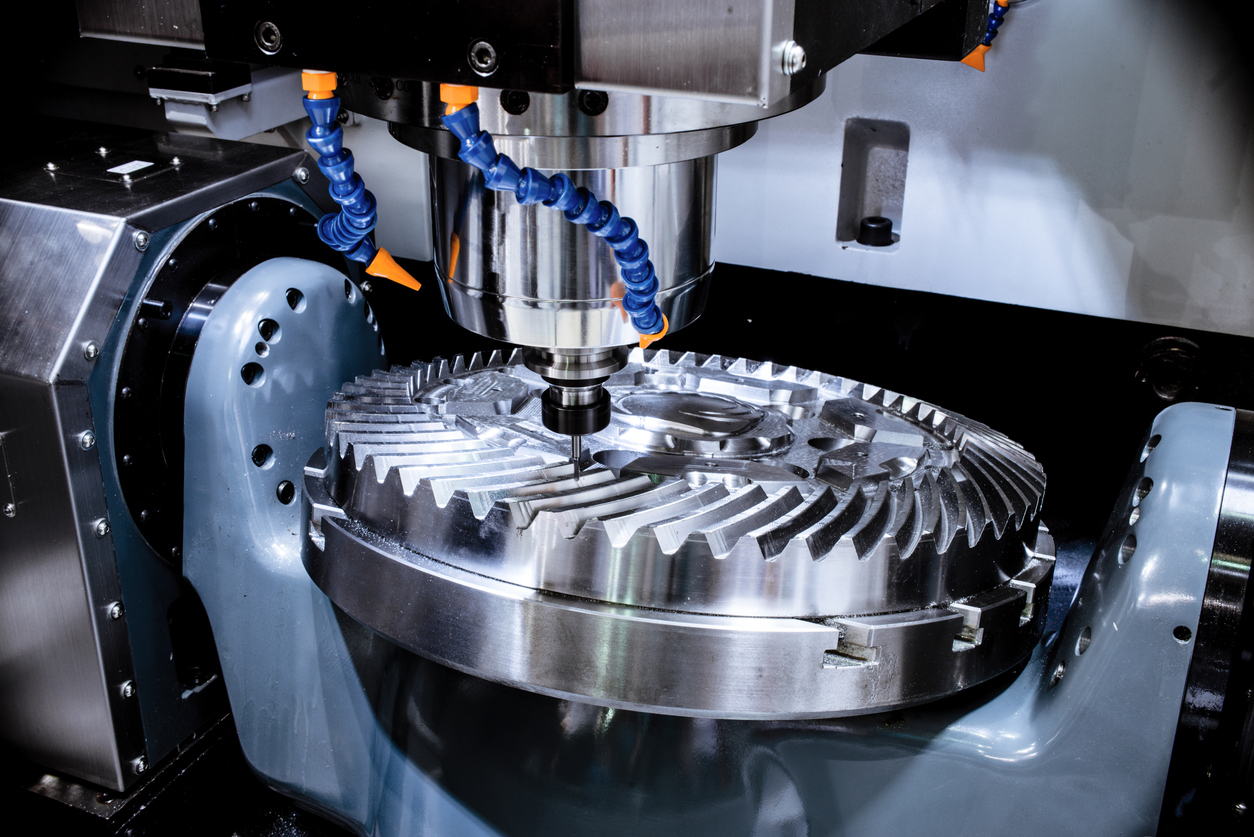

One invaluable precision machining process is CNC milling, which has a key role in several vital industries. CNC milling components can offer many advantages, especially in products that are used in critical applications. Often, these components require exacting tolerances and high precision. Because they are used in sometimes life-saving instances, these products must be able to perform as expected in order to prevent catastrophes. Here, we will take a closer look at how CNC milling components can optimize product performance and lead to more efficient production.

Ready to boost the quality of your precision machined components? Reach out to the expert team at Alco today to get started.

Understanding CNC Milling: The Benefits of This Key Process

It’s important to understand what the CNC milling process entails. Here, a computer numerical control machine is programmed to remove material from a workpiece until the desired geometry is achieved.

This process is highly precise and offers many benefits. CNC milled components are accurate and improve product performance. This process can easily craft parts with tight tolerances that match precise specifications. CNC milling is also incredibly efficient. Because these machines can run automatically, they can produce components quickly, making it a much more efficient manufacturing process than other methods. That also means it is well-suited for high-volume production.

Because of this improved efficiency, producing CNC milled components results in shortened lead times. CNC milling machines are also highly automated, reducing the need for workers and lowering labor costs. One person can manage multiple machines at once, and this equipment also leads to a safer environment for workers because workers don’t need to crouch when using them. Because this process is also highly accurate, you won’t need to spend extra time and money on reworks and excess material, making CNC milling a cost-effective method.

A Closer Look at Real Applications for CNC Milling Components

For all of the reasons outlined above, you’ll find CNC milling components used within various key industries. These critical industries include:

- Aerospace and Defense: CNC milling is a popular manufacturing method used for various components in aircraft, weapons, and landing gear components. Tight tolerances are required in this industry to ensure these essential products function as needed.

- Electrical: Expect to find CNC milling components to be used in the electrical industry for printed circuit boards, electronic switches, and more. CNC milling is efficient, making it the perfect process for creating electrical components needed in other products.

- Medical Devices: The medical industry requires consistent, accurate components, which is why CNC milling is an ideal solution. These parts are used for implantable devices, catheters, surgical equipment, and more.

- Automotive: Reliable, high-volume production is necessary in the automotive process, making CNC milling the perfect process. This manufacturing method is used for engine and transmission components.

Partner with Alco for Your Next Project

At Alco, we offer expert CNC milling services, leveraging the latest technology to provide our customers with exceptional quality components. We have a full suite of specialized equipment that allows us to craft complex geometries that are critical within a number of key industries.

Our other extensive capabilities include Swiss machining, multi-spindle screw machining, tooling design, and more. We can offer start-to-finish support so your final product matches your precise requirements and also adhere to stringent industry standards. We hold a variety of ISO accreditations, and are also a member of the NAHAD, NFPA, PMPA, and MACNY, demonstrating our commitment to quality.

At Alco, we’re dedicated to fast quoting and attentive customer support because we are passionate about crafting exceptional CNC milling components. Get in touch with Alco today to learn more about how we can elevate your projects.