In nearly every industry, offering customized solutions that meet a customer’s unique needs is always valued. The precision machining industry is no different. One manufacturing method that offers tailored services and efficient production is CNC milling. Utilized within many different industries, this process is cost-effective, precise, and fast, saving customers both time and money, and allowing them to maintain a competitive advantage. Here, we’ll take a closer look at how CNC milling parts can be tailored to offer solutions for complex applications.

Are you ready to improve the standard of your components? Get in touch with Alco today to see how we can level up your next project.

The CNC Milling Process and Its Benefits

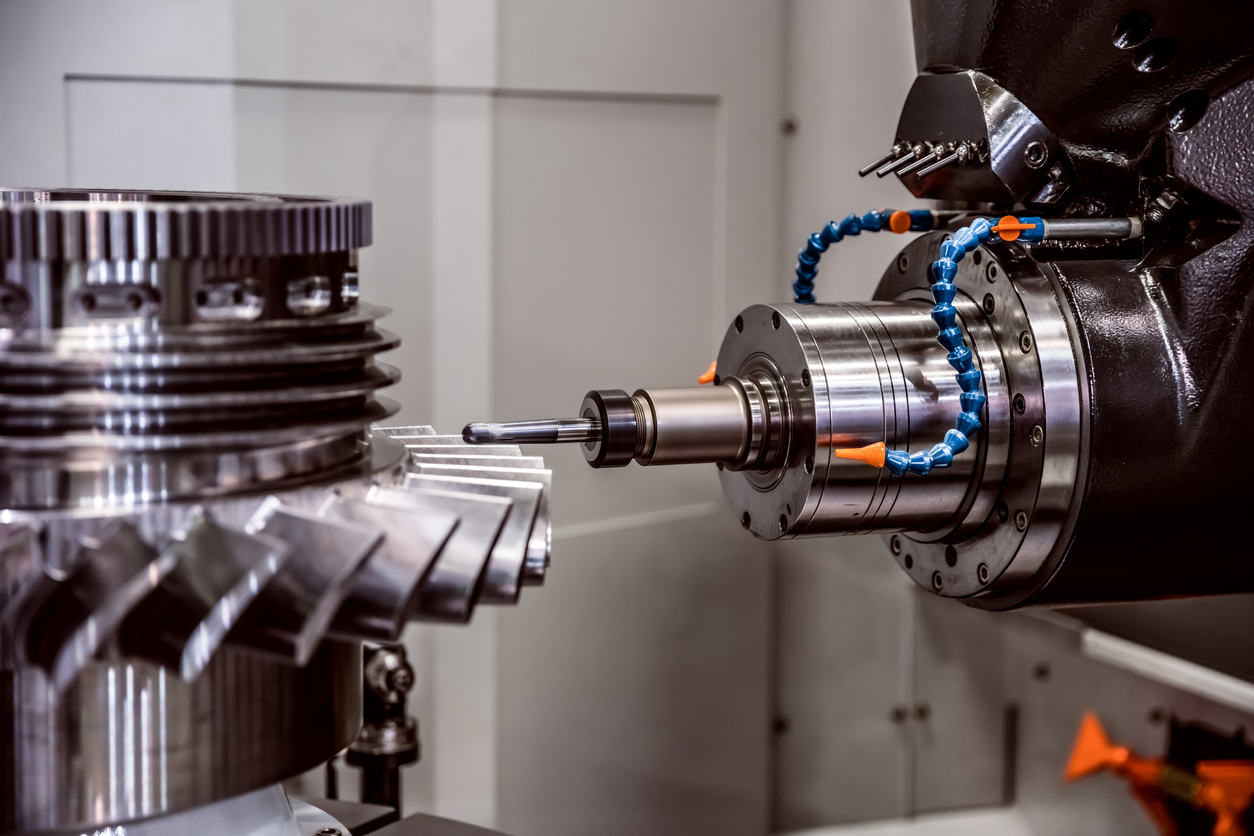

Let’s examine the CNC milling process in more detail. This method involves a computer-controlled machine that directs a rotating cutting tool to remove material from a workpiece until the desired shape is reached. This automated process removes material and produces precise components that perform as needed.

The benefits of CNC milling are expansive. This manufacturing process results in enhanced precision and accuracy, resulting in exact dimensions required for the part to perform as expected. It also can create parts with complex geometries, and can easily adapt to different designs. CNC milling is a versatile process, and can work with a variety of different materials.

With this enhanced quality, you can also realize faster production times because automation allows for continuous operation. These parts are consistent and reliable. Since this manufacturing method produces easily repeatable parts, it is suitable for high-volume production, resulting in less material waste and lower labor costs. Precise, efficient, and affordable: CNC milling is a precision machining service that offers many enticing advantages.

Versatile and Adaptable: Different Industries that Use CNC Milling

Various industries use CNC milling because of these clear benefits. The aerospace industry utilizes these parts for landing gear components and aircraft metal parts. Defense needs these vital parts for engine components found in military vehicles, as well as parts for weapons. These high-performing parts are important for these critical industries because they function as required in these essential applications.

Automotive products use CNC milling for engine components, pistons, valves, and more. These parts must be consistent and reliable, and CNC milling’s high-volume capabilities are beneficial in this industry. The medical and pharmaceutical industry also utilizes this manufacturing method for surgical instruments, implantable devices, and more because these parts are precise and high-quality.

Choose Alco for Exceptional CNC Milling Parts

If you’re searching for precision, Alco can help. We provide expert milling and turning services, crafting components with complex dimensions and intricate designs. Our other capabilities are vast, and include Swiss machining, multi-spindle screw machining, and more. We also offer prototyping and secondary processes, taking your project from concept to creation and beyond.

Alco holds a variety of ISO accreditations, and we’re also a member of the NAHAD, NFPA, PMPA, and MACNY, demonstrating our commitment to crafting quality precision machined components. With fast quoting, inventory programs, outstanding customer support and exceptional results, turn to Alco to enhance the quality of your next project. Connect with us today to learn more.