The precision machining world has been rocked by numerous disruptions in recent years: supply chain delays, global instability, pandemic challenges, stringent importing regulations, and more. As a result, a number of companies are choosing to partner with domestic manufacturers, rather than international suppliers. According to recent research, 69% of U.S. manufacturers have begun reshoring their supply chains across various industries, including precision machining.

This means that domestic precision machine shops have new opportunities to reach their customers, but before selecting your precision machine shop, there are several important factors you need to consider. Let’s take a closer look at them here.

3 Essential Questions to Ask Your Precision Machine Shop

1. What Services Do They Provide?

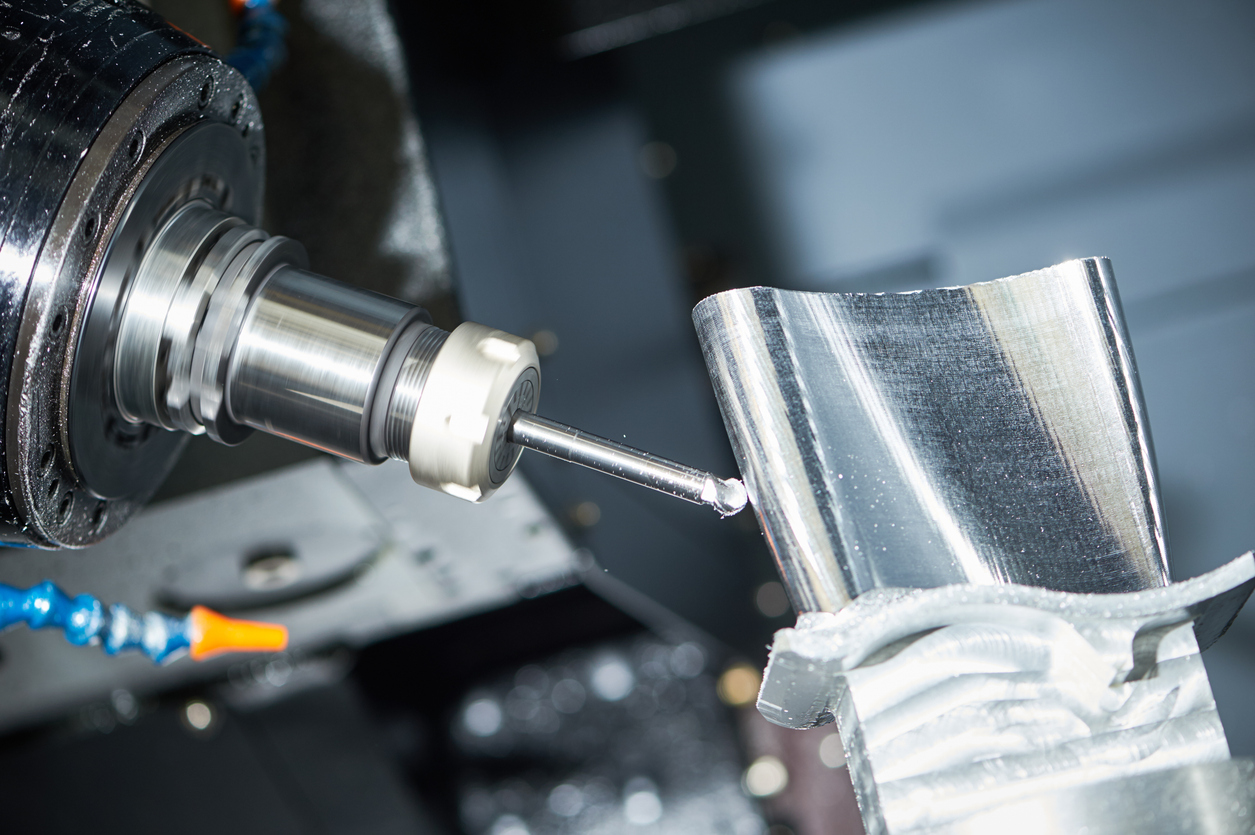

It’s important to ensure that your precision machine shop has the wide breadth of services you may require to finish a part to your satisfaction. That means you may need prototype or engineering services to refine your product before manufacturing even begins. Then consider their precision machining services, as well as secondary processes, because contracting outside vendors to finish your product can be costly.

Fortunately, Alco is able to support your project from conception to completion. We offer robust tooling design and prototyping services that help bring your vision to life. Our machining capabilities include milling and turning, hydromats, Swiss machining, and multi-spindle screw machining. Finally, we also offer extensive secondary processes that finish your product to meet your specifications. Our services include annealing, plating, assembly, heat treating, anodizing and more. With our comprehensive capabilities, we’re able to match your precision machining needs.

2. What is Their Experience?

Your precision machining partner should be experienced in adhering to industry-specific requirements in order to make sure parts function as needed. Different markets have different needs. Is your precision machine shop able to handle your specifications?

At Alco, we have over 50 years of experience helping businesses in a variety of industries receive the high-performance precision machined components they need. We’ve crafted specialized parts for aerospace and defense, electrical, medical devices, automotive and more, and we have the necessary expertise to provide you with the components that will match your application.

3. Do They Have the Capabilities to Offer High-Volume Manufacturing?

High-volume precision machining can be an affordable and time-saving option that leaves you with exceptional quality components. Various manufacturing methods, like milling and turning or Swiss machining, are repeatable and reliable, producing consistent precision machined parts on a large scale.

High-volume manufacturing can not only boost quality, but can save both time and money because of reduced set-ups and a decrease in the need for multiple shipments. Alco has the capabilities to provide you with the cost-saving advantages that high-volume production affords. We have multiple locations from Michigan to New York, and each facility is organized based on machine type and expertise, allowing us to achieve lean manufacturing and competitive prices.

The Benefits of Partnering with a Domestic Precision Machine Shop

With tightening international regulations and costly shipping delays, partnering with a domestic precision machine shop offers numerous advantages over overseas suppliers. Domestic manufacturers are more cost-effective because you don’t have to worry about expensive shipping costs or additional expenses, like tariffs.

Domestic precision machine shops also offer more streamlined production. You don’t have to worry about finding, hiring, and managing multiple vendors for your project, and with enhanced communication between yourself and your manufacturer, you can also expect better overall quality for your components. With shorter lead times, your products will also reach the market faster, allowing you to maintain a competitive edge.

Alco is Your Trusted Precision Machining Partner

Alco is well-equipped to provide you with the quality components you need for your application. We have a long tenure as a respected manufacturer in the precision machining industry, and our services are expansive, allowing us to create exceptional parts tailored to your requirements. If you’re ready to partner with a precision machine shop that will elevate the standard of your components, reach out to Alco today to get started.